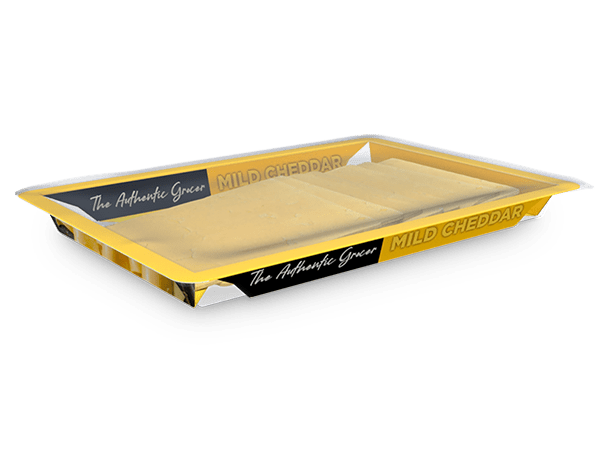

PaperLite Barrier Material for Trays

Part of our tray portfolio, PaperLite is a fiber-based flexible barrier material that is supplied on a reel for forming on standard thermoforming lines.

The high fiber content is achieved without compromising barrier performance and hence offers product protection and shelf-life comparable to traditional plastic trays.

PaperLite is ideal for chilled foods, helping brand owners and retailers meet their targets on plastic reduction while offering an effective, attractive pack.

PaperLite is compatible with a comprehensive range of lidding films to ensure perfect pack integrity, optimum shelf-life, and process efficiency.

PaperLite’s depth is from flat to around 20mm, dependent on tray shape.