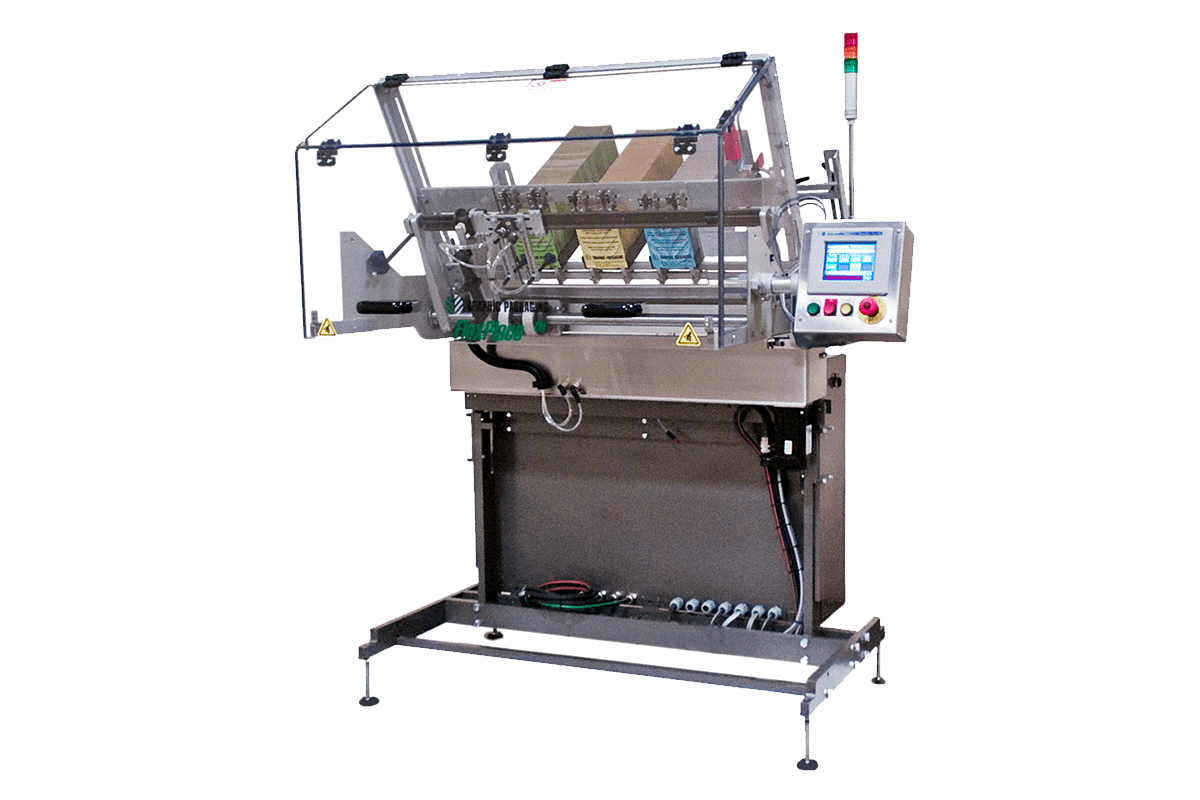

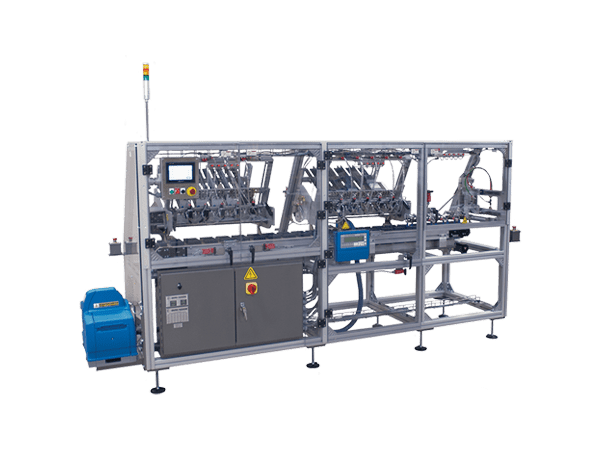

FlexPlace™

The FlexPlace™ machine offers a broad range of placement options for picking and placing a variety of stackable items into a continuous-motion production line without a stopped target for accurate placement. It includes the functionality to speed match, tip, collate items or provide an extended run time in one machine.

This product may not be available in your region. Please contact us for more information.

FlexPlace Benefits

Speed Matching

- Maintains continuous motion of existing target product

- Allows higher speeds than indexing motion

- No need to stop the target for the placement of product

Tipping

- Provides the ability to automate tipping applications

- Ability to pick, then place while matching speed with the target product

- Matching speed enables increased placement accuracy

Collating

- Ability to pick different products on-demand based on the flow of incoming product

- Ideal for mixing and matching of products for a variety of pack type applications

Run Time

- Ability to have multiple lanes with the same product to provide extended run times without operator intervention

- Allows operators time to tend to other areas of the packaging line

- Longer supply of product in a smaller footprint

See FlexPlace in Action

Providing a continuous-motion placement with an indexing machine for collation, speed match, or extended run times.

FlexPlace Specifications

Speeds

- Up to 50 cycles per minute per lane, dependent on product characteristics

Product Configuration

- Multiple magazine lanes to provide higher output.

- Magazine lanes perpendicular to flow or in-line with flow

Machine Models

- 24”, 36” and 48” width models

- Custom widths available

Electrical and Air Requirements

- Control voltage: 24 VDC

- Supply voltage options:

- 230 VAC, single phase

- 230 VAC, three phase

- 480 VAC, three phase

- 80 psi clean/dry air (equivalent to class 3 or better). CFM is dependent on the vacuum system supplied.

FlexPlace Features

Standard Features

- Servo-drive controls

- Transversing vacuum stems to match the speed of the target product

- Inclined product magazine with multiple lanes

- Floor-mounted stand with casters for mobility and adjustable foot pads

- PLC controlled – Allen Bradley

- Touch screen operator interface

- Interface with existing production line

Optional Features

- Quick-change magazine assembly and stem tooling for quick, repeatable changeovers.

- Multi-lane options

- Pneumatic product escapements depending on product characteristics

- Signal options: photo eye, batch counter, fixed cycle rate signal, timer to signal, encoder, or customer to signal

- Low magazine or missed item signal options

Related Machinery

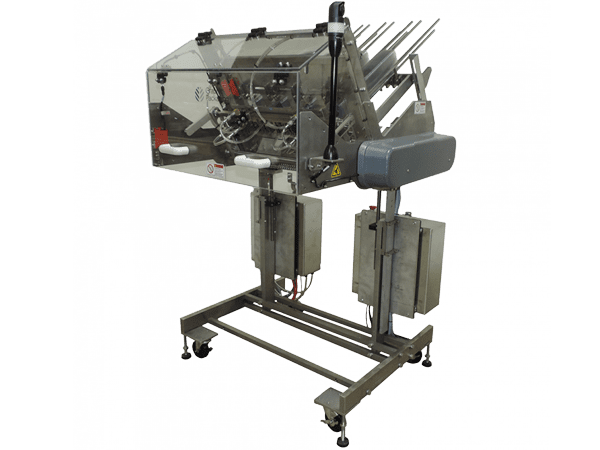

Reciprocating Pick and Place Machines

A standalone, flexible, intermittent-motion machine designed for picking and placing a variety of stackable items at the front of a production line.

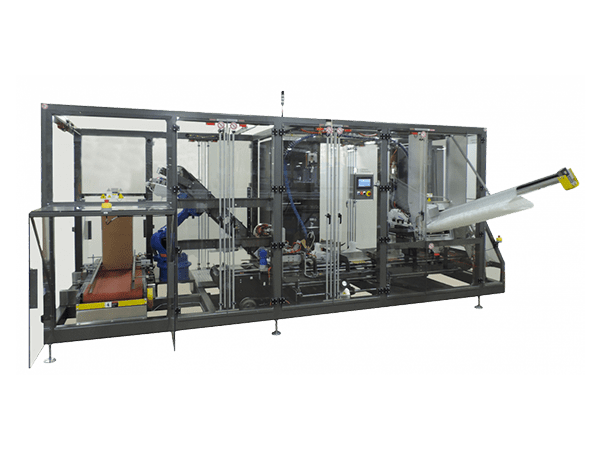

Custom Robotic Machinery Solutions

Robotic packaging solutions customized for your product application.

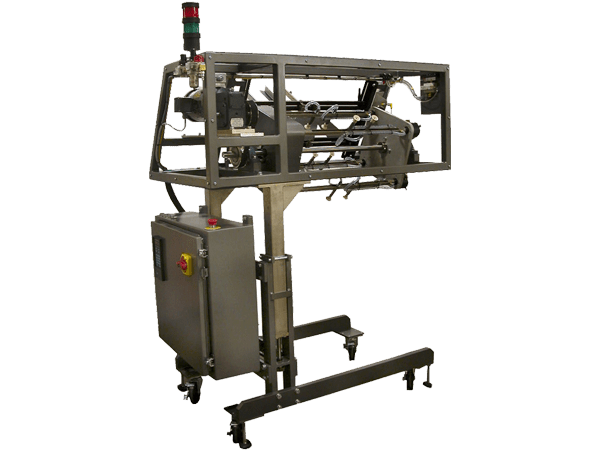

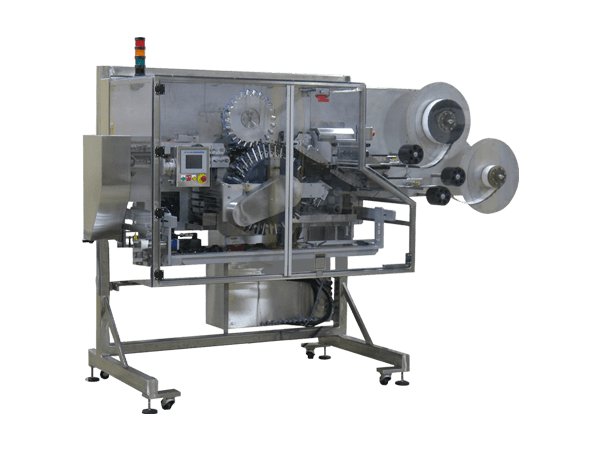

Rotary Vacuum Placers

Rotary vacuum placers are flexible, continuous-motion machines designed for picking a variety of stackable items at high speed with placement onto or into another product on a conveyor or flight system.

Servo-Driven Rotary Placer

A standalone, continuous motion machine that is designed to pick a variety of stackable items, with precise placement onto another product in a production line.

Card Carrier Assembly Machine

The card carrier assembly machine is a flexible, intermittent-motion packaging system designed to attach gift cards onto printed carriers for point-of-purchase hanging displays.

ElastiTag® Applicator

The ElastiTag® applicator applies ElastiTag® neck tags to bottles and containers automatically at high speed.

Related Products

MicroRite™ Microwavable and Ovenable Pressed Trays and Bowls

MicroRite™ products manage microwave energy to provide even heating during cooking.

Pressed Board Trays and Bowls

Pressed board trays and bowls provide consumers with an economical, paperboard alternative to CPET and PE plastic trays.

Susceptor Cartons, Trays, and Bowls

Our susceptor cartons, trays, and bowls deliver consistent browning and crisping of food.

PaperSeal™ Cook Tray

PaperSeal™ Cook is a paperboard tray for oven and microwave-ready chilled and frozen food applications.

PaperSeal™ Original Tray

The PaperSeal™ Original paperboard tray, an alternative to traditional MAP trays, is ideal for fresh and processed meat and fish applications, salads, fruit, pasta, and more.

ProducePack™ Punnet Tray

The ProducePack™ Punnet is a top-sealed paperboard tray for applications such as cherry tomatoes, mushrooms, grapes, and berries that offers superior recyclability compared to plastic alternatives, with enhanced on-shelf differentiation.