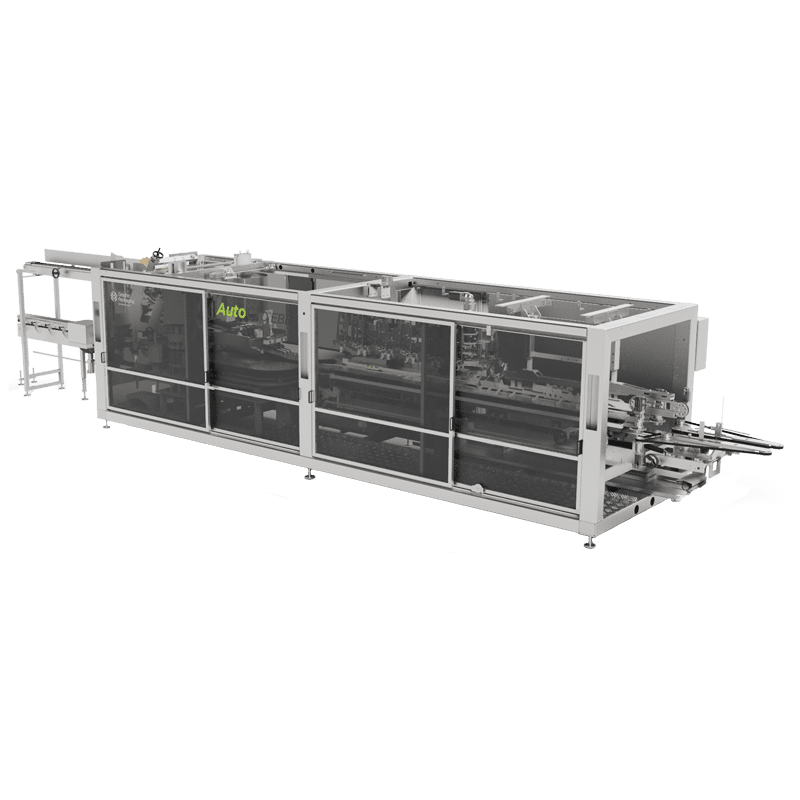

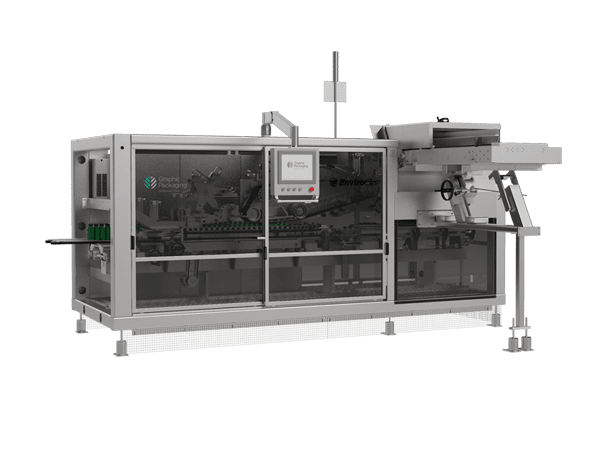

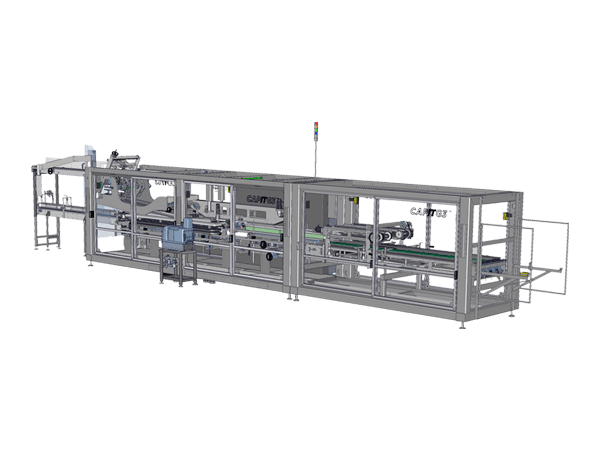

AutoClip™ EBB1200

AutoClip™ EBB1200 is designed to apply EnviroClip™ Beam, our glue-free, minimal material clip to a full range of round and square PET bottles with neck rings.

The orientation module allows PET bottles to retain orientation for higher impact on the retail shelf, or for operational purposes, such as the requirement for a barcode cover.

Speeds of up to 230 packs per minute can be achieved, providing 4-, 6-, and 8- pack formats, with tool-free changeovers that are quick, simple, and repeatable.