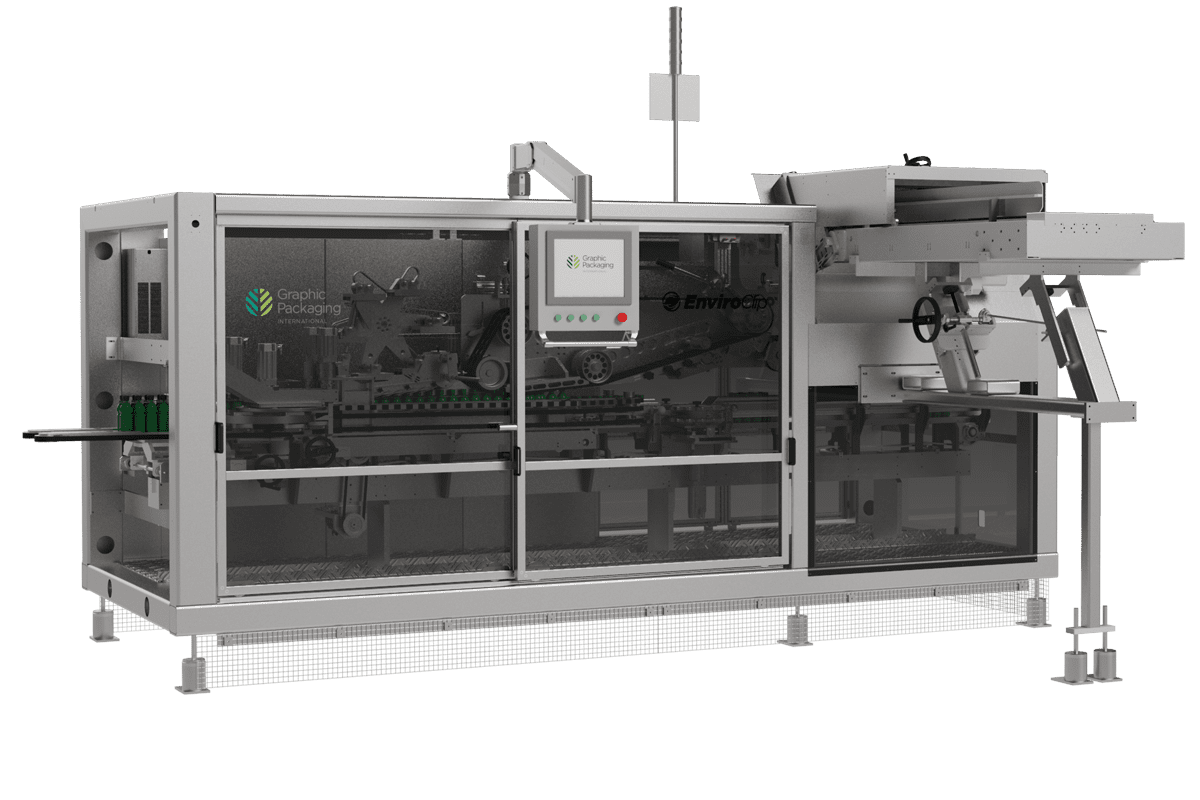

AutoClip™ EBR1200

The AutoClip™ EBR1200 is a small-footprint system designed to apply the EnviroClip™ clip-style multipack solution to round and square PET bottles. The machine can achieve speeds of up to 340 packs per minute, provides 4-, 6-, and 8-pack formats, and has tool-free changeovers.

AutoClip EBR1200 has a powered clip magazine with a high capacity and an integrated down product detection on the infeed conveyor. The machine produces clips with minimal material and no glue that offer an alternative to plastic rings and shrink film.