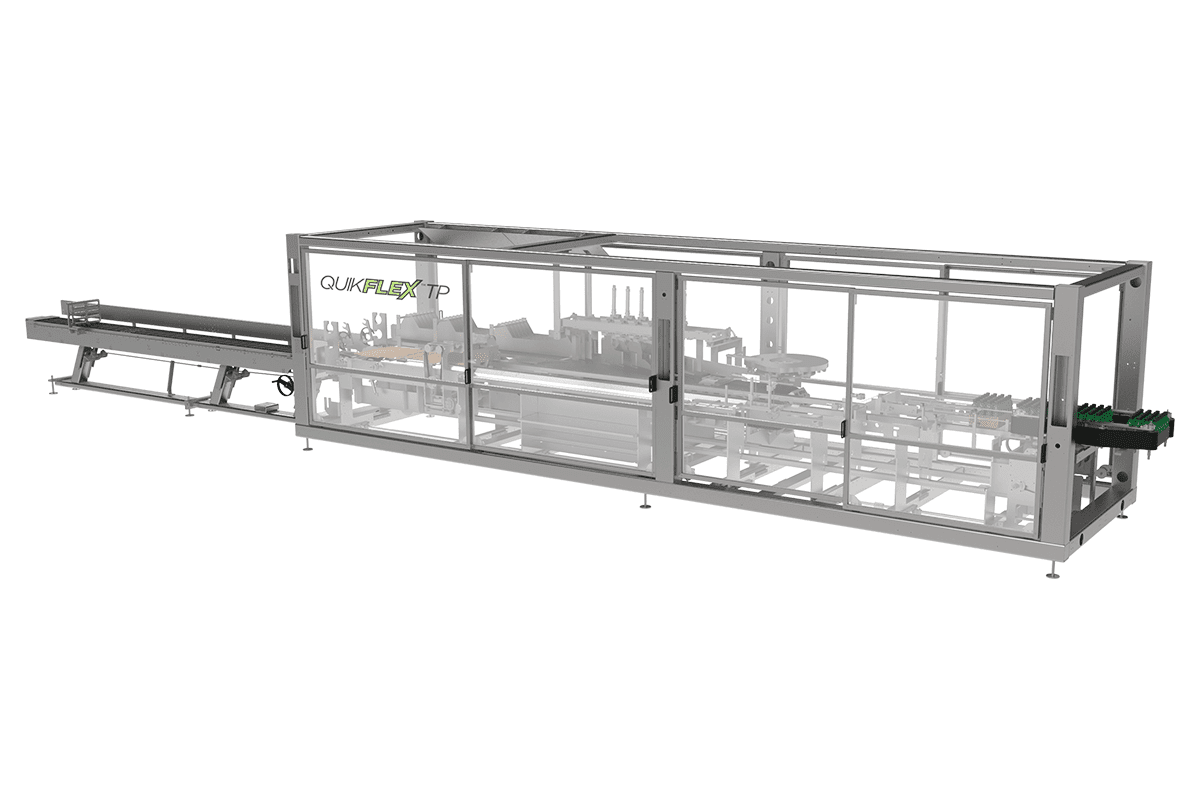

QuikFlex™ TP

QuikFlex™ TP is a high-speed system for producing corrugated or paperboard trays to pack loose items such as cans and bottles.

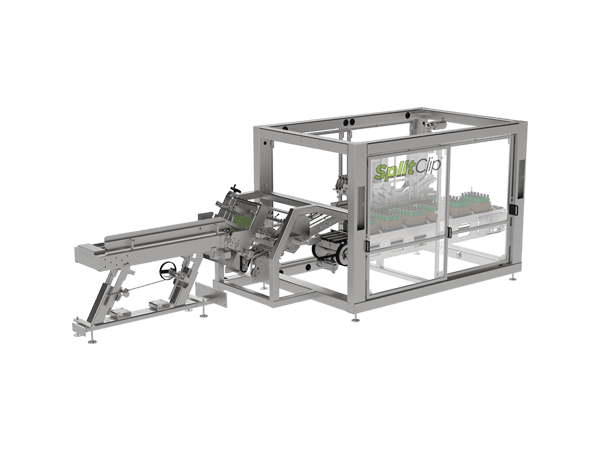

It has the flexibility to create trays with different wall heights and corner styles for ultimate efficiency and protection. It is also able to work as a module for our clip applicator, AutoClip SplitClip™.